PKD

New member

- Joined

- May 28, 2023

- Messages

- 11

- Reaction score

- 6

- Points

- 3

- Genesis Model Year

- 2020

- Genesis Model Type

- Genesis G70

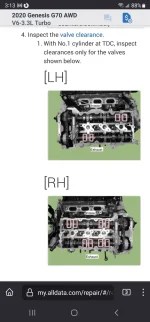

Hello everyone, new to forum and a Technician since 1985. Was curious about the ticking noise at start up on my G70 3.3T HTRAC Sport, 14K miles and found answers and questions on here. So I thought I might share some tech for folks like us who like our cars and like to be informed.

I know of "solid-lifters" in hotrods and race engines, but had never really studied them. I knew they were always noisier and that was just "solid-lifters".

So one or more members here knows they are solid lifters and is right in that if the noise goes away fairly quickly that it's technically normal.

Now the important part to me was why it's normal. I believe understanding brings peace and wisdom, "no worries".

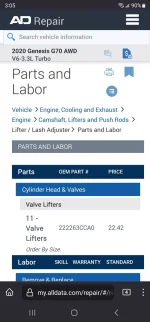

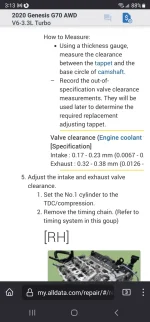

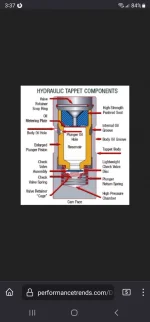

So solid lifters are just that, solid round lifters that only expand with heat and therfore the space between the rod to the rocker arm is called "lash". It's what's created when adjusting the rocker arms.

Most engine builders in a "factory" setting would leave thousandths to allow for warm up expansion so that the valves don't end up hung open on their respective "stroke"; exhaust or compression stroke.

Zero lash would basically take away tick on cold start but could cause wear because of being tight once expanded or the other mentioned above. "Zero is "perfect", race engines are often set that way.

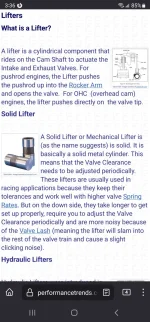

Solid lifters are better because the don't have anything else needed to work, they are "solid", therefore the perform better, more efficiently, consistently they Rev higher with more stability and therefore make more power.

Hydraulic lifters have many parts inside them to work, need oil pressure to work and they change in length as needed based solely on the spring inside and oil psi delivered. This being said, each lifter can work differently based on if the spring is identical inside and the pressure to each lifter is identical; which is an engineering calculation or lack thereof. Basically an easier way to not have an exact need for valves to have to be exact; therfore not synced an inconsistencies in power. Less time for assembly lines, more money for Dealers.

Customers would never notice this and would like the quiet motor. That is until they use the wrong oil or cheap oil or the wrong weight, which changes valve train performance.

There are vehicles out there that end up with misfires or "drivability" problems (codes) that "technicians" end up having to change the oil and filter type because the oil change place or customer was running the wrong weight oil; hence hydraulic lifters. Parts often replaced or engines until manufacturers get them back under warranty and find or write-up a TSB to dealers that problem is only an oil lift problems or recommend different weight or updated filters or to just change oil back to factory oil and then retest.

I went out on the web with the basic question, Solid vs. Hydraulic lifters?

You'll find we have a more precise "race style" engine and yes, lifters can be adjusted, but comments say they rarely will ever need it in the consumer market.

If the independent Dealerships cared enough or were "smart"/technical enough they would give this answer to "us" type customers and we would walk away smiling or cheering, instead of them just saying it's normal. And or the manufacturers could and sometimes do, send out "customer letters" with the lengthier explanation which would improve there profits and retention to brand.

I was in Dealerships for 16yrs. and unfortunately they normally aren't informed of why and their techs don't normally care to share if they did know because they would loose money explaining it and most people wouldn't understand or might not appreciate or believe them.

Worst of all most techs just don't care, and I say this from experience, caring cost money in the short run. But can create huge gains in years and decades and incredible brand retention.

Hence the vicious cycle of most car folks and especially enthusiasts finding disappointing and truly bad experiences everywhere they go.

Hope this helps, sorry so long, but this is why most techs just don't help; I'm not most, I'm very rare; and I say this humbly, not bragging.

Oh yeah, and if you look at the Motor Trend piece I attached, you will see that Hydraulic was a cheap easy way for manufacturers to make engines quicker and less precise because Hydraulic zero lashes itself and "absorbs" imperfections in valve train, but as you'll read, that's not good ultimately. Just Google the title from screen shot or type in>>

>>"Solid vs. Hydraulic lifters" for tons of articles and real-time dynos with change out of Hydraulic to Solid lifters; Torq and Horsepower gained.

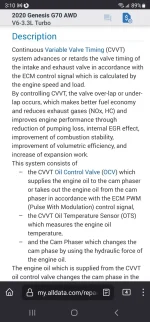

Our Twin turbo 3.3's have tons of torq which spins motor up very fast, so technically it seems the quality we see inside these cars is in the engine also.

By the way, Torq is what gets ya going(off the line), H.P. is what keeps ya going, fact.

And 5.0L, if you have solid lifters, they've taken time to make yours better also.

We all know that better isn't normally easier, and easy ain't always good!

PKD

I know of "solid-lifters" in hotrods and race engines, but had never really studied them. I knew they were always noisier and that was just "solid-lifters".

So one or more members here knows they are solid lifters and is right in that if the noise goes away fairly quickly that it's technically normal.

Now the important part to me was why it's normal. I believe understanding brings peace and wisdom, "no worries".

So solid lifters are just that, solid round lifters that only expand with heat and therfore the space between the rod to the rocker arm is called "lash". It's what's created when adjusting the rocker arms.

Most engine builders in a "factory" setting would leave thousandths to allow for warm up expansion so that the valves don't end up hung open on their respective "stroke"; exhaust or compression stroke.

Zero lash would basically take away tick on cold start but could cause wear because of being tight once expanded or the other mentioned above. "Zero is "perfect", race engines are often set that way.

Solid lifters are better because the don't have anything else needed to work, they are "solid", therefore the perform better, more efficiently, consistently they Rev higher with more stability and therefore make more power.

Hydraulic lifters have many parts inside them to work, need oil pressure to work and they change in length as needed based solely on the spring inside and oil psi delivered. This being said, each lifter can work differently based on if the spring is identical inside and the pressure to each lifter is identical; which is an engineering calculation or lack thereof. Basically an easier way to not have an exact need for valves to have to be exact; therfore not synced an inconsistencies in power. Less time for assembly lines, more money for Dealers.

Customers would never notice this and would like the quiet motor. That is until they use the wrong oil or cheap oil or the wrong weight, which changes valve train performance.

There are vehicles out there that end up with misfires or "drivability" problems (codes) that "technicians" end up having to change the oil and filter type because the oil change place or customer was running the wrong weight oil; hence hydraulic lifters. Parts often replaced or engines until manufacturers get them back under warranty and find or write-up a TSB to dealers that problem is only an oil lift problems or recommend different weight or updated filters or to just change oil back to factory oil and then retest.

I went out on the web with the basic question, Solid vs. Hydraulic lifters?

You'll find we have a more precise "race style" engine and yes, lifters can be adjusted, but comments say they rarely will ever need it in the consumer market.

If the independent Dealerships cared enough or were "smart"/technical enough they would give this answer to "us" type customers and we would walk away smiling or cheering, instead of them just saying it's normal. And or the manufacturers could and sometimes do, send out "customer letters" with the lengthier explanation which would improve there profits and retention to brand.

I was in Dealerships for 16yrs. and unfortunately they normally aren't informed of why and their techs don't normally care to share if they did know because they would loose money explaining it and most people wouldn't understand or might not appreciate or believe them.

Worst of all most techs just don't care, and I say this from experience, caring cost money in the short run. But can create huge gains in years and decades and incredible brand retention.

Hence the vicious cycle of most car folks and especially enthusiasts finding disappointing and truly bad experiences everywhere they go.

Hope this helps, sorry so long, but this is why most techs just don't help; I'm not most, I'm very rare; and I say this humbly, not bragging.

Oh yeah, and if you look at the Motor Trend piece I attached, you will see that Hydraulic was a cheap easy way for manufacturers to make engines quicker and less precise because Hydraulic zero lashes itself and "absorbs" imperfections in valve train, but as you'll read, that's not good ultimately. Just Google the title from screen shot or type in>>

>>"Solid vs. Hydraulic lifters" for tons of articles and real-time dynos with change out of Hydraulic to Solid lifters; Torq and Horsepower gained.

Our Twin turbo 3.3's have tons of torq which spins motor up very fast, so technically it seems the quality we see inside these cars is in the engine also.

By the way, Torq is what gets ya going(off the line), H.P. is what keeps ya going, fact.

And 5.0L, if you have solid lifters, they've taken time to make yours better also.

We all know that better isn't normally easier, and easy ain't always good!

PKD

Attachments

Last edited: