john massaria

Registered Member

- Joined

- Oct 2, 2018

- Messages

- 83

- Reaction score

- 39

- Points

- 18

- Genesis Model Type

- Equus (2011-2016)

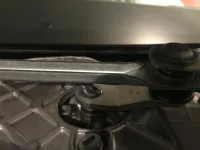

So at 79K miles my 2014 Equus Signature with Hermes light addition (love that look- and I did it myself- I posted pics b4-but I digress) had a problem while driving in rain- the wipers stopped!!! After arriving at my home in the garage, I took it all apart- wiper arms- all the plastic covers off, the cowl off and took out entire wiper blade motor arm components- I dis assembled the motor and transmission and bushing brushes inside to check all is good- cog wheel inside transmission also good but I rotated it to the other side which has no wear- re assembled. None of these things were the issue- the issue was the short control arm connection to the assembly- but the iron like black cog wheel bolt connects to the aluminum thread also cog like- but the there is no carter pin- and not enough room to try to bolt anything on - what to do to make up the space? I used JB Weld for metal- I will supply pictures-

I read older Genesis owners have recall on motor for wipers- called Hyundai about Equus- no dice they said no recall.... good thing I'm handy- the total price for the entire assembly is over $1K which includes new motor and arms but not the wiper blade arms- the only thing that failed is the weakest link - this iron bolt which connects to a short aluminum arm and you need to get both assembly and motor for both to work they do not sell the two pieces separate and used ones will be worn out most likely giving similar problems- like I said I will post pictures.... all is better now thanks to JB Weld and being patient and handy.... hope this helps others.

I read older Genesis owners have recall on motor for wipers- called Hyundai about Equus- no dice they said no recall.... good thing I'm handy- the total price for the entire assembly is over $1K which includes new motor and arms but not the wiper blade arms- the only thing that failed is the weakest link - this iron bolt which connects to a short aluminum arm and you need to get both assembly and motor for both to work they do not sell the two pieces separate and used ones will be worn out most likely giving similar problems- like I said I will post pictures.... all is better now thanks to JB Weld and being patient and handy.... hope this helps others.